Recubridor ultrasónico por pulverización centrífuga (300-3000 RPM, oblea máxima de 12")

El pulverizador/aplicador de adhesivo ultrasónico VTC-300USS permite controlar con precisión la relación estequiométrica de la solución, la velocidad de pulverización, el tamaño de las partículas y otros parámetros. El diámetro de los sustratos que puede recubrir/aplicar es de hasta 300 mm (12").

- Shenyang Kejing

- Shenyang, China

- 22 días laborables

- 50 juegos

- información

Garantía

Un año de garantía limitada con soporte de por vida (no incluye piezas oxidadas debido a condiciones de almacenamiento inadecuadas).

Logística

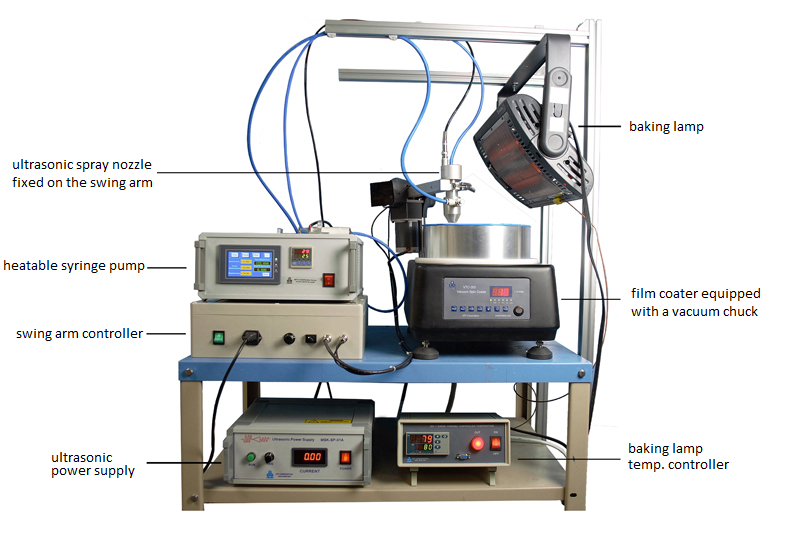

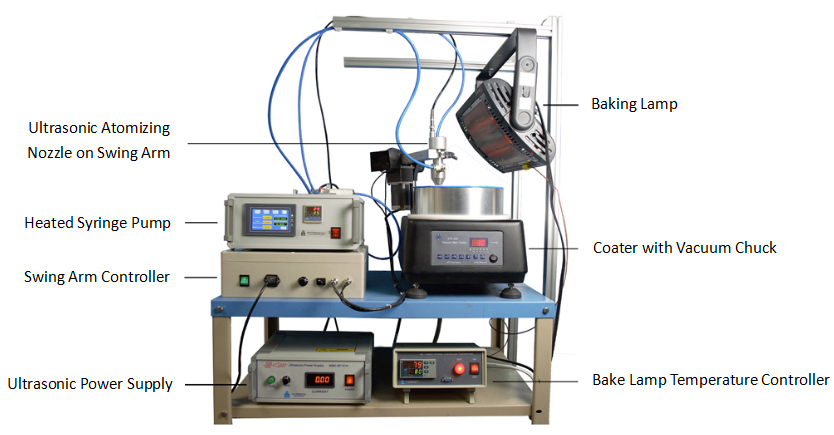

The VTC-300USS uses a stepper motor and microprocessor-controlled volumetric pump to accurately deliver the coating solution, which can be either heated or unheated. The ultrasonic atomizer, mounted on a swingable support arm, ensures excellent coating uniformity. The mist particles ejected from the atomizer are deposited onto the substrate to form the desired material structure, enabling the preparation of thin micro- and nano-scale films.

The coater can hold substrates up to 12 inches (305 mm) in diameter and supports substrate heating for rapid film drying (with optional Heating & Baking Module).

This deposition technique is particularly suitable for oxide film formation and has a long history in the preparation of transparent electrodes. It is now widely applied in the fabrication of perovskite solar cells and other advanced thin-film materials.

Main Features

1. Ultrasonic atomization method — The solution is atomized and sprayed onto the substrate to form the desired material structure. An optional upper heating and baking module can be equipped to enhance film formation. This material preparation technique is particularly suitable for oxide deposition and has a long history of application in transparent electrode fabrication. It is now widely used in the production of perovskite solar cells.

2. Combines the advantages of spin coating and spray coating, enabling the formation of dense and uniform liquid-phase coatings on large substrates.

3. Applicable to a wide range of processes, including low-temperature precipitation (e.g., for RF/microwave ferrite deposition), polymer coatings, powder and composite coatings, and coatings on patterned or uneven substrates.

4. The system supports operation in independent spin and independent spray modes.

Technical Parameters

Product Name | VTC-300USS Ultrasonic Spin-Spray Coater/Glue Sprayer | |

| Product Model | VTC-300USS | |

| Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong earthquake source and corrosive gas around the equipment. 3. Water: sewage drainage 4. Electricity: single phase: AC220V 50Hz 10A . 5. Gas: ① vacuum negative pressure (vacuum pump) suction flow rate not less than 70L/min ② compressed gas (air compressor) 6. Workbench: recommended 1500mm×600mm×700mm load-bearing 100kg or more (solid cement platform is better) 7. Ventilation device: no special requirements | |

| The main parameters | Rotating host 1. Host power supply port Power socket with insurance: AC220V 50Hz 10A 2. Host power ≤300W 3. Sample tray (suction cup) Polypropylene vacuum suction cup: φ203 mm, upper limit of adsorption substrate diameter: φ305 mm 4. Operation mode:Single direction counterclockwise operation 5. Spindle speed:100-3000rpm effective 6. Speed stability:±2% 7. Spindle control mode:Stepless speed regulation 8. Swing arm swing angle:30°-75° 9. Swing arm control mode:Stepless speed regulation 10. Total weight:65kg 11. Equipment dimensions:540mm×720mm×240 mm | |

Ultrasonic atomization 1. Ultrasonic power supply port: AC220V 50Hz 2. Ultrasonic power: 200W 3. Particle size: 10-20um 4. Flow rate: 0.6pl-4ml/min 5. Viscosity: ≤100cps 6. Solid content: ≤10% 7. Fluid viscosity range: 1-50mpa.s (cP) 8. Recommended compressed air range for aqueous solution: ~2psi 9. Atomizing nozzle: Cylindrical tip: narrower spray diameter ~20mm 1 pc 10. Ultrasonic nozzle frequency: 40KHz±10%: Amplitude power gear: 1, 2, 3 gears adjustable | ||

| Injection pump system 1. Pump power port DC24V (standard "power adapter" IN: AC100-240V 50/60Hz OUT: DC24V 3.75A) 2. Pump power: ≤50W 3. Dimensions: 250×65×50 mm 4. Injection speed: 0.001-20 mm/min 5. Fine-tuning speed: 0.001-10 mm/min 6. Syringe diameter: 0.04-30 mm 7. Standard needle volume: 20ml 8. Stroke setting range: 0.01-90 mm | ||

| Baking lamp - optional 1. Heating power: 2kW 2. Heating power supply: AC220V 50Hz 3. Host size: 660mm×410mm×635mm 4. Heating method: infrared heating lamp: radiation baking 5. Heating temperature: RT-80℃ | ||

| ||

Standard accessories:

| Serial number | Name | Quantity | Image link |

| 1 | Rotating mechanism | 1 | - |

| 2 | Ultrasonic atomization power supply + atomization nozzle | 1 | - |

| 3 | Single-line liquid supply system | 1 | - |

| 4 | Oil-free pump | 1 | - |

Optional accessories:

| Serial number | Name | Function Category | Image link |

| 1 | Multi-channel (heatable) liquid supply system, drying device, etc. | (Optional) | - |

| 2 | Heating lamps and controls Dual heating lamps (up to 1000W, up to 80ºC) with thermocouples and temperature controllers to heat the substrate by radiation (up to 65ºC on 12" metal substrates) | (Optional) |  |

| 3 | It is recommended that you place the spin coater in a fume hood to address health and safety issues | (Optional) |  |

| 4 | Compressed gas atomizing nozzles are available with NRTL certification | (Optional) |  |

| 5 | Customized multi-nozzles available upon request | (Optional) |  |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics