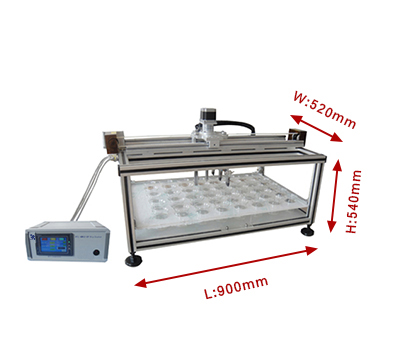

Recubridor de inmersión de precisión con control PLC de 5×8 posiciones

El recubridor por inmersión PTL-MM02-8P es un equipo de precisión especialmente diseñado para el estudio de películas líquidas en crecimiento. Incorpora un sistema de control de velocidad de alta precisión y una terminal de entrada de parámetros en pantalla táctil para controlar automáticamente la extracción y el recubrimiento de cinco muestras simultáneamente.

- Shenyang Kejing

- Shenyang, China

- 22 días laborables

- 50 juegos

- información

Introducción del producto

La máquina de recubrimiento por tracción PTL-MM02-8P es un dispositivo de recubrimiento por tracción multiestación de precisión milimétrica, diseñado para instituciones de investigación. Se utiliza principalmente para preparar películas multicapa en fase líquida sobre una o más muestras en diferentes fases líquidas. La máquina presenta una estructura compacta, un funcionamiento sencillo y es fácil de transportar, y se ha utilizado ampliamente en universidades, institutos de investigación y laboratorios corporativos.

Características principales

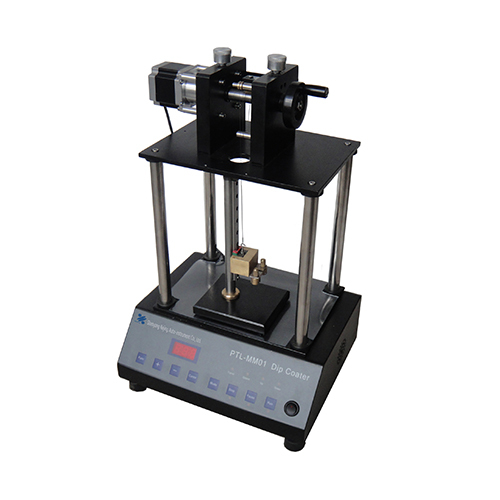

1. Múltiples muestras/Multiestación:Admite recubrimiento por inmersión y tracción simultáneos de hasta 5 muestras en hasta 8 materiales de fase líquida diferentes, con repetición de ciclo hasta 999 veces para recubrimiento multicapa.

2. Configuración de parámetros independientes:Cada una de las 8 estaciones puede configurar de forma independiente la velocidad de tracción, el tiempo de inmersión y el tiempo de secado para satisfacer diversos requisitos del proceso.

3. Fácil operación:Equipado con una pantalla táctil a color de 4,3 pulgadas con una interfaz sencilla e intuitiva para una operación cómoda.

4. Control de alta precisión:El programa PLC controla un motor paso a paso de alta precisión, con correas de distribución y tornillos de bolas como componentes de transmisión para garantizar un movimiento más preciso.

5. Optimización del espacio:Diseño compacto con alta relación costo-beneficio, ahorrando espacio en el laboratorio.

Parámetros técnicos

Nombre del producto | Recubridor por inmersión PTL-MM02-8P | |

Modelo de producto | PTL-MM02-8P | |

Condiciones de instalación | 1. Fuente de alimentación: CA 220 V 50/60 Hz. 2. Entorno de funcionamiento: Temperatura 25℃ ±15℃, humedad 55%RH ±10%; libre de polvo, libre de vibraciones y libre de gases inflamables, explosivos o corrosivos. | |

Parámetros principales (Especificación) | 1. Voltaje de funcionamiento del host: CC 24 V, 5 A (estándar: adaptador de corriente CA 100-240 V) 2. Potencia total: 100 W 3. Tipo: Programable – Tipo de temperatura ambiente 4. Motor de accionamiento: motor paso a paso de alta precisión 5. Rango de ajuste de velocidad: · Eje X (posicionamiento): 500~5000 mm/min · Eje Z (tracción): 1~200 mm/min 6. Tiempo de permanencia: 1~999 s 7. Tiempo de secado: 1~999 s 8. Carrera de tracción: 1~65 mm 9. Recuento de ciclos: 1~999 ciclos 10. Estaciones de extracción de muestras: 5 posiciones (pueden contener de 1 a 5 sustratos de muestra) 11. Estaciones de inmersión: 8 grupos (5 posiciones de vasos de líquido por grupo) 12. Profundidad de inmersión efectiva: ≤65 mm 13. Rango de tamaño del sustrato de muestra: L75 mm × W25 mm × T2,5 mm 14. Carga máxima de tracción: ≤250 g 15. Especificaciones de la taza (vaso de precipitados): 100 ml 16. Pantalla y control: Pantalla táctil a color de 4,3 pulgadas | |

17. Especificaciones del producto: · Dimensiones: 900 mm × 520 mm × 540 mm · Peso: ≈20 kg |

| |

Accesorios estándar

| No. | Nombre | Cantidad | Imagen |

| 1 | Placa de fijación del vaso de precipitados | 1 pieza | - |

| 2 | Placa de fijación de abrazadera | 1 pieza | - |

| 3 | Cubilete | 40 piezas | - |

| 4 | Abrazadera | 5 piezas | - |

| 5 | Cubierta protectora | 2 piezas | - |

Accesorios opcionales

| No. | Nombre | Categoría de función | Imagen |

| 1 | Se pueden personalizar diferentes tamaños de vasos y porta vasos según las necesidades del usuario. | Opcional | - |

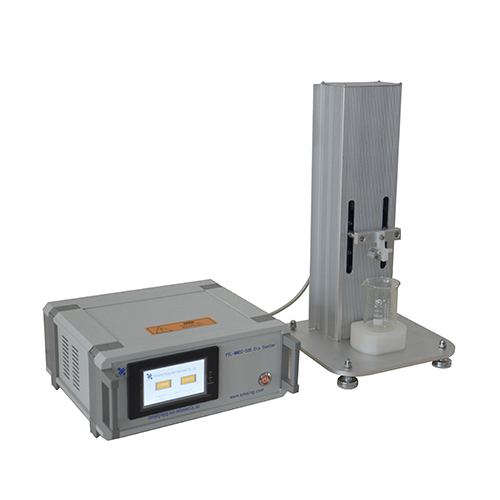

| 2 | Tanque de agua termostático (Potencia: 800 W; Temperatura termostática: RT-70 °C; Precisión de temperatura: ±1 °C independientemente del impacto ambiental; Volumen: 25 L) | Opcional | - |

Garantía

Garantía limitada de un año con soporte de por vida (sin incluir piezas oxidadas debido a condiciones de almacenamiento inadecuadas)

Logística